Heat Shrink, Polyolefin, 2:1, Black, 0.034" Exp ID

$500.00

6/bag

Min. Quantity: 1

In-Stock: 7

Ships in 1-2 business days

Product Details

| Min Exp ID (in) | 0.034 |

|---|---|

| Max Recovered ID (in) | 0.02 |

| Recovered Wall Thickness (in) | 0.005 |

| Note | Wall thickness provided is the final recovered wall thickness at max recovered ID. Tubing will be supplied thinner before shrinking. |

| Shrink Ratio | 2:1 |

| Color | Black |

| Material | Polyolefin |

| Length (in) | 60 |

| Shrink Temperature | ~ 220° F/105° C |

| Dielectric Strength | 1, 000 volts/mil |

| Tubing Certification | USP Class VI |

| Sterilization | Stable with gamma, e-beam, or EtO sterilization. Test for autoclave or repeat use. |

| Longitudinal Shrinkage | 10% |

| Flexural Modulus | 135, 000 psi |

| Packaging | 6/bag |

| Datasheet | https://chamfr.com/wp-content/uploads/2024/03/COBALT_Polyolefin_SS_03.24-HR25.pdf |

| Shipping Dimensions | 72 × 4 × 4 in |

| Shipping Weight | 7 lbs |

Product Description

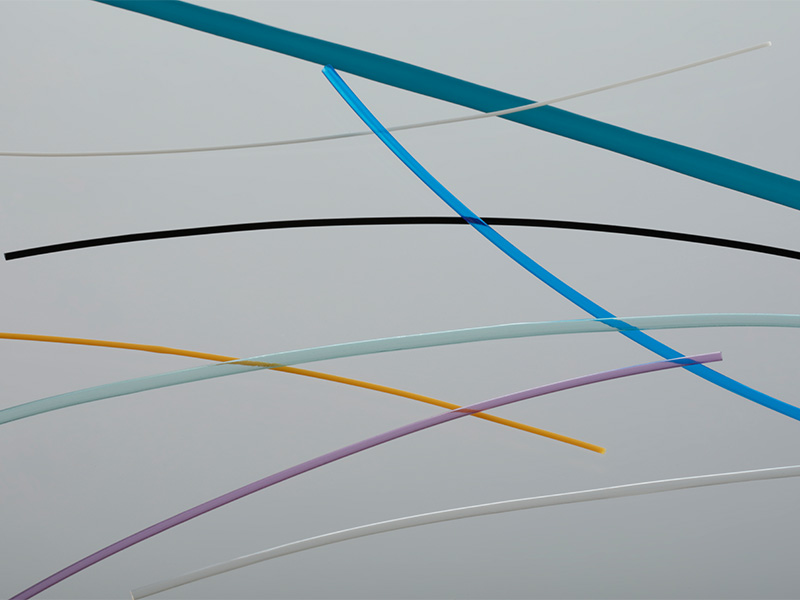

Polyolefin Heat Shrink Tubing is flexible, thin, and has high compressive strength, making it ideal for electrical insulation, guidewire applications, and strain relief. This durable tubing makes an effective moisture/vapor barrier. In addition, Polyolefin Heat Shrink Tubing features excellent dielectric strength, very low shrink temperature, high shrink ratio, rapid recovery, excellent concentricity, and controlled longitudinal shrinkage (<10%). This tubing is a possible substitute for PET heat shrink tubing or FEP heat shrink tubing, particularly for low-temperature applications.

Applications

Insulation for electrosurgical instruments

Jacket for laparoscopic devices

Coating for tapered guidewire

Wire insulation

Cover for coils & braids

Jacket for laser-cut hypotubes

Strain relief

Reinforcement to protect splices & components

Thermoplastic welding

Probe coating

Is there something you’d like to see in our marketplace?

We’re continually adding items and would love to hear your ideas.