Unlocking Design Freedom in Medical Devices with Laser Cut Tubing

Medical device engineers are under constant pressure to deliver devices that are smaller, stronger, and more versatile, often within aggressive timelines. Prototyping bottlenecks and design limitations can slow progress, leaving R&D teams searching for new ways to accelerate innovation.

In our recent webinar, “Unlocking Design Freedom for Rapid Iteration with Laser Microfabricated Hypotubes,” CEO of Sublime Laser, Todd Turnlund, shared exactly how laser processing is driving innovation in R&D, featuring:

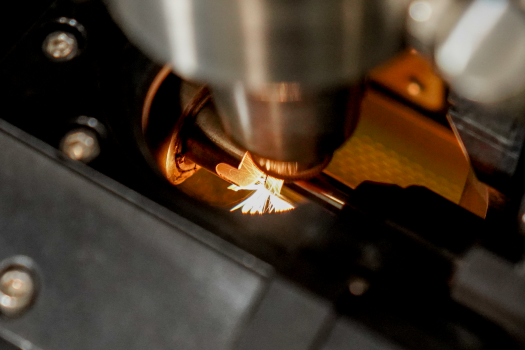

- A live laser cutting demonstration.

- Technical deep dives into customizable solutions and precision techniques.

- An interactive Q&A session, facilitated by the Chamfr team.

This webinar marked part four of Chamfr’s educational series designed to pull back the curtain on how medical devices are really made – from design decisions to assembly to sourcing components at speed.

Want to see the live demo in action? Sign up below to access the full recording →

Laser Cut Tubing: Transforming Medical Device Development

Laser cut tubing has become an essential enabler for catheter and interventional device development. It allows design teams to customize patterns, integrate complex features, and refine performance in ways that traditional machining cannot. From balancing torque and flexibility in catheter shafts to achieving ultra-fine precision in hypotube cuts, this technology is reshaping what’s possible.

Customizable Solutions for Complex Designs

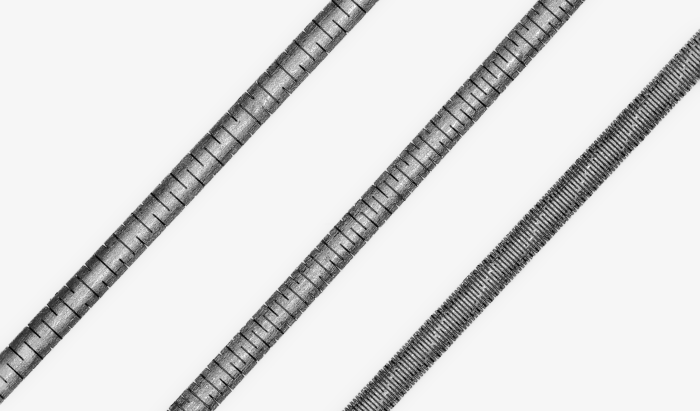

Complex medical devices often require unique cut patterns, such as spirals, brickwork, or hybrid geometries, to achieve desired performance. With tube laser cutting services, these patterns can be customized quickly, enabling engineers to fine-tune designs for pushability, kink resistance, or steerability without waiting weeks for tooling.

Precision for Smaller, Smarter Devices

Minimally invasive devices demand features measured in thousandths of an inch. Laser processing offers sub-micron accuracy with clean edges, allowing for tighter tolerances and reduced risk of structural defects. This level of precision is critical to safety and performance.

Balancing Torque and Flexibility

One of the recurring challenges in catheter design is creating shafts that are flexible enough to navigate tortuous anatomy, yet rigid enough to transmit torque effectively. In the webinar, Sublime Laser experts demonstrated how specific cut patterns, which are achievable only with laser machining, allow engineers to dial in that balance.

Leveraging Industry Expertise

Beyond equipment, the expertise behind the process matters. Sublime Laser’s team emphasized how their combination of femtosecond and fiber systems, coupled with years of medical device experience, allows them to guide customers toward the right solution. Engineers aren’t just getting parts cut. They’re gaining insight into design trade-offs and manufacturability.

Engineering Insights

Sublime Laser’s technical expertise, as an ISO-certified company, shared in the webinar provided valuable engineering insights to help understand and overcome the toughest design challenges.

Understanding Laser Platforms

- Femtosecond lasers excel at producing smooth edges and eliminating heat-affected zones, ideal for delicate features in nitinol or stainless steel.

- Fiber lasers provide higher throughput at lower cost, making them effective for scaling production.

- Sublime Laser’s expertise in both laser types provides flexibility for different geometries and materials.

Live Demo: Cutting Nitinol Tubes

Attendees watched as Sublime Laser cut a 0.025” OD nitinol hypotube, demonstrating advanced patterns under microscope-level magnification. The live view highlighted the system’s capability to produce intricate geometries with consistent widths.

Real-World Applications

The team discussed how laser cut tubing is applied across medical devices, including:

- Neurovascular catheters requiring extreme flexibility.

- Peripheral vascular devices balancing durability and trackability.

- Cardiovascular implants demanding high fatigue resistance.

Material Choice and Performance

Selecting nitinol vs. stainless steel impacts how the tube interacts with laser processing. The panel explained that nitinol’s superelasticity demands ultrafast pulses for best edge quality, while stainless steel can often be processed effectively with fiber systems.

Design Trade-Offs and Manufacturability

Engineers were encouraged to consider how different cut patterns influence fatigue life, kink resistance, and torque response. Sublime Laser’s expertise helps teams avoid pitfalls early in development.

Balancing Innovation and Production Readiness

One of the most valuable discussions centered on scalability: ensuring that the same precision tube laser techniques used in R&D can be applied to scaled manufacturing without sacrificing quality.

Sourcing Options Through Chamfr

Attendees learned that Sublime’s parts can be sourced directly through Chamfr’s digital marketplace, with 30 SKUs available for rapid delivery. This integration allows engineers to quickly access both off-the-shelf components and customizable prototypes.

Final Thoughts on Laser Cut Tubing

The medical device industry continues to push the boundaries of what’s possible with minimally invasive devices. Laser cut tubing has become a foundational technology in this innovation, enabling customizable solutions, precise performance, and the ability to balance torque with flexibility in medical device design.

By combining advanced equipment with deep expertise, partners like Sublime Laser help engineers turn concepts into clinical realities faster and with greater confidence.

If you’re exploring new ways to accelerate R&D and improve your next device, be sure to download the full recording and see how these innovations can support your work.