Accelerate Catheter Development with BayCath’s Braided Shaft for Catheters

Why Braided Shafts Matter in Catheter Design

Getting the right balance of torque response, kink resistance, and flexibility is one of the toughest challenges in catheter engineering. A braided shaft for catheters provides the reinforcement backbone that gives designers control over pushability, torque transmission, and trackability while maintaining a thin profile.

Now available on Chamfr, BayCath Medical’s 304 stainless steel braided shafts offer engineers an easy way to evaluate and order high-performance reinforcement structures without waiting on long lead times or quotes.

BayCath’s 304 SS Braided Shafts: Specs at a Glance

BayCath has introduced 19 new SKUs of braided shafts for catheters, engineered for prototyping, design iterations, and early-stage builds.

- Material: 304 Stainless Steel (SS)

- Length: 60 inches

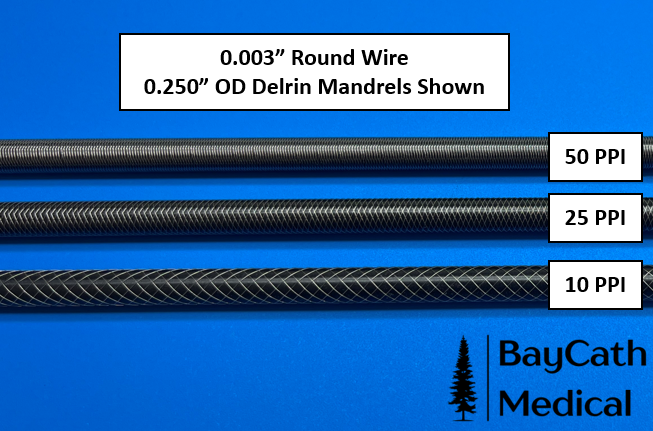

- PPI: 5, 10, 25, 50

- Inner Diameters (IDs): 0.188″, 0.25″, 0.375″

- Configurations: Flat or Round

These shafts are suitable for a wide range of minimally invasive applications, from cardiovascular to neurovascular to peripheral devices.

Application Guidance for Braided Shafts

Choosing the right braided shaft for catheters is about managing trade-offs. Flexibility comes at the expense of torque response and vice versa. BayCath’s wire types and PPI options let engineers fine-tune shaft performance for specific applications:

PPI:

- 5–10 PPI: Wider braid angle, lower density. Provides greater flexibility and pushability, but reduced torque control. Often used in larger-diameter or peripheral catheters.

- 25 PPI: Balanced coverage. Delivers a mix of flexibility and torque response, making it well-suited for general cardiovascular builds.

- 50 PPI: Narrow braid angle, higher density. Offers maximum torque transmission and kink resistance, but less flexibility. Ideal for neurovascular catheters and highly steerable shafts.

Flat vs. Round Wire Braid:

- Flat Wire (5 & 10 PPI): Wider surface coverage at low density. Good for designs where flexibility and thin wall construction are priorities, such as peripheral shafts or early neurovascular prototypes.

- Round Wire (10, 25, 50 PPI): Stronger reinforcement at higher densities, with easier processing in shaft assembly. Common in cardiovascular and neurovascular designs where torque control and durability are critical.

By stocking multiple sizes and braid densities, BayCath helps design teams dial in performance without delays.

Build Faster, With Fewer Roadblocks

Ready to reduce sourcing delays and accelerate your catheter design process? BayCath’s ready-to-ship braided shafts for catheters give you immediate access to high-performance reinforcement, with no quotes, no onboarding, and no long lead times. Pair them with liners, jackets, and marker bands from the Chamfr marketplace to build your entire shaft architecture in one place.

Start designing smarter with BayCath braided shafts on Chamfr

Build Your Entire Catheter Shaft on Chamfr

These braided shafts pair seamlessly with other shaft-building essentials available on Chamfr:

- PTFE Liners: Create low-friction inner lumens for guidewire tracking and fluid delivery

- Heat Shrink Tubing: Fuse shaft layers with precision and dimensional consistency

- Multi-Lumen Extrusions: Enable steerable or dual-purpose designs with complex geometries

- Mandrels: Maintain dimensional stability during manufacturing

- Marker Bands: Add radiopacity for precise positioning

Instead of managing multiple vendor relationships, Chamfr offers a single marketplace with 13,000+ in-stock MedTech components ready to ship. This means fewer purchase orders, fewer delays, and a more efficient prototyping cycle.