How to Predict Recovered Wall Thickness for Pebax and Polyolefin Heat Shrink Tubing

In this sponsored technical blog post, Cobalt Polymers explains how Pebax® and Polyolefin Heat Shrink Tubing behave during recovery and how engineers can predict final wall thickness for their medical device designs.

Pebax & Polyolefin Heat Shrink Tubing play a critical role in medical device manufacturing. They provide thin, uniform jackets around components such as laser-cut, coils, or guidewires, adding protection and insulation without significantly increasing the device profile. For engineers building catheter-based systems, understanding how these types of tubing behave as they shrink is essential to achieving the right fit, flexibility, and performance.

One question we hear frequently is: “How do I know how thick the tubing wall will be after it’s applied?”

That answer depends on the material, shrink ratio, and how completely the tubing is recovered around your substrate.

A Simple Analogy: The Party Balloon

A good way to visualize this concept is with a balloon. When fully inflated, the balloon’s wall is very thin. As the air is released, the wall thickens. The same mass of material is distributed over a smaller area.

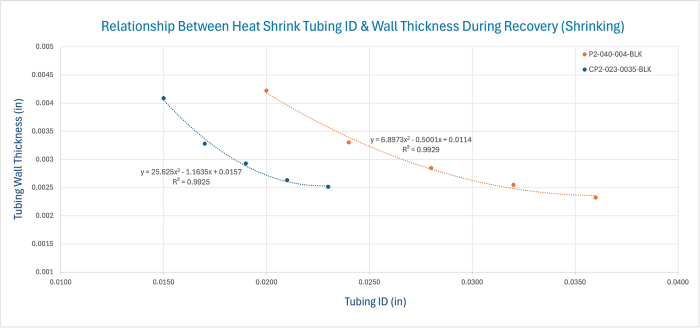

Heat shrink tubing behaves similarly. As the tubing shrinks down over a mandrel or device, its inner diameter (ID) decreases while the wall thickness increases. Unlike a balloon, though, high-performance tubing such as Pebax or Polyolefin is engineered to shrink in a controlled, predictable way from lot to lot.

Understanding Recovered (Post-Shrink) Tubing Wall Thickness

Cobalt Polymers lists a Recovered Tubing Wall Thickness on each data sheet. This value represents the wall thickness when the tubing is fully recovered to its smallest possible ID.

However, many medical device assemblies use tubing that is only partially recovered. When the tubing is not shrunk all the way down, the resulting wall is thinner and more flexible than the value shown on the data sheet.

For example, if you are jacketing a 0.030-inch OD laser-cut hypotube with 72D 2:1 ratio Pebax Heat Shrink Tubing that has an expanded ID of 0.036 inch (shown in orange in the graph), the tubing will partially recover to fit tightly over the laser-cut hypotube. At that degree of recovery, the wall thickness will be approximately 0.0025 inch, thinner than the fully recovered value.

Engineers often overlook this nuance, assuming that the recovered wall thickness listed on the data sheet represents the actual final wall. In reality, if your substrate diameter is larger than the tubing’s recovered ID, the tubing will stop shrinking once it makes contact, resulting in a thinner, more flexible jacket.

Being able to predict that relationship between recovered ID, substrate OD, and wall thickness is key to selecting the right tubing for your design.

Pebax Heat Shrink Tubing: Flexibility with Strength

Pebax Heat Shrink Tubing is known for being flexible, thin and durable. Available in durometers from 40D to 74D, it gives engineers control over stiffness and flexibility to meet specific design needs. When brought to its shrinking temperature, Pebax Heat Shrink Tubing will thermally bond to an underlying material, whether it’s a metal or a polymer. This eliminates delamination issues and the need for an adhesive or tie layer.

Key Properties

- Shrink temperature: ~340°F (171°C)

- Durometers: 40D to 74D

- Elongation at break: 300% (for 72D)

- Tensile strength: 7,500 psi

- Dielectric strength: >500 volts/mil

- Certification: USP Class VI

- Sterilization: Stable with gamma, e-beam or EtO sterilization

- Longitudinal shrinkage: <10%

Typical Applications

- Jacket for laser-cut hypotube

- Coating for tapered guidewire

- Outer layer for catheter shaft

- Cover for coils and braids

- Wire insulation

- Strain relief

- Wire bundling

Polyolefin Heat Shrink Tubing: High Compressive Strength

Polyolefin Heat Shrink Tubing delivers high compressive strength that makes it ideal for electrical insulation and strain relief, often eliminating the need for adhesive. It also shrinks at a low temperature, making it suitable for assemblies that include temperature-sensitive materials. Engineers choose Polyolefin for its combination of flexibility, durability, and strength.

Key Properties

- Shrink temperature: ~220°F (105°C)

- Durometer (Shore D): 63

- Dielectric strength: 1000 volts/mil

- Flexural modulus: 135,000 psi

- Longitudinal shrinkage: <10%

- Can remain on device or be removed

- USP Class VI certified

Typical Applications

- Insulation for electrosurgical instruments

- Jacket for laparoscopic devices

- Coating for tapered guidewire

- Wire insulation

- Cover for coils & braids

- Reinforcement to protect splices & components

- Thermoplastic welding

Choosing Between 2:1 and 4:1 Shrink Ratios

Cobalt Polymers offers both 2:1 and 4:1 shrink ratios in Pebax and Polyolefin tubing.

- 2:1 ratio: Common for general catheter and wire jacketing. It provides excellent control and minimal longitudinal shrinkage.

- 4:1 ratio: Useful when the starting ID must be much larger than the final substrate, or when the goal is an ultra-thin final wall (<1 mil). As noted in Cobalt Polymers’ 4:1 Pro Tips blog, higher-ratio heat shrink offers flexibility but can require more careful processing.

Why Predicting Tubing Wall Thickness Matters

During catheter and guidewire development, engineers often iterate designs to balance flexibility, profile, and pushability. Selecting tubing with the right post-shrink wall thickness can:

- Prevent unnecessary stiffness in distal segments

- Ensure smooth transitions between bonded layers

- Reduce the need for rework or alternate durometer testing

- Shorten the overall design cycle

Accurately predicting recovered wall thickness enables you to model how a tubing layer affects your final device profile, helping to minimize trial-and-error during process development.

Need help applying or selecting the right tubing?

Cobalt Polymers’ dedicated Applications Lab supports engineers using Pebax and Polyolefin Heat Shrink Tubing. The team can help you choose the right material, size, shrink ratio, and wall thickness; develop your heating process; and troubleshoot challenges with bonding or recovery.

If you’re not sure which tubing to start with, complete our quick identify the tight tubing form to get tailored recommendations from Cobalt’s technical team.

Explore Cobalt Heat Shrink Tubing on Chamfr

Cobalt Polymers’ Pebax and Polyolefin Heat Shrink Tubing are available in multiple durometers, sizes, colors, shrink ratios, and wall thicknesses on Chamfr.

Not finding what you’re looking for? Submit an RFQ to Cobalt Polymers directly through Chamfr and connect with the team for custom configurations.