Rapid Prototyping Tools: Threaded Insert Installer & EZ Motion Suite from Pipeline Engineering

In medical device product development, the tools you use are just as critical as the components you select. That’s why Chamfr continues to expand beyond parts—with high-performance tools that help R&D teams design, prototype, test, and iterate faster.

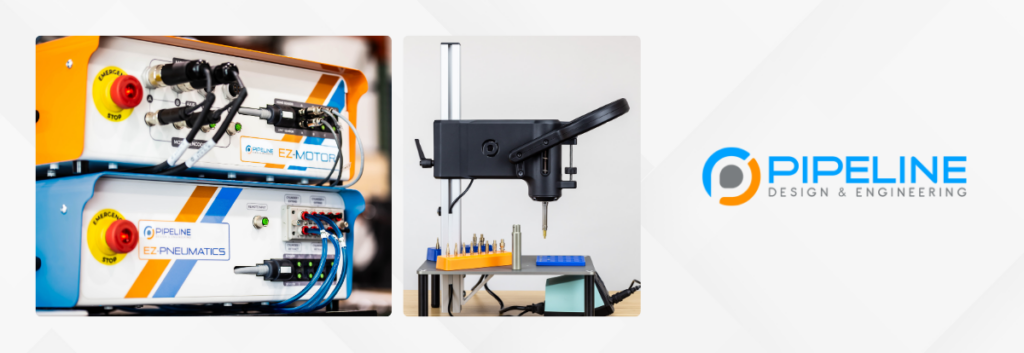

We’re excited to welcome Pipeline Design & Engineering as a new supplier on Chamfr. Known for their precision-built systems that support rapid development cycles, Pipeline brings two powerful tools to the Equipment, Fixtures & Tools category:

These tools were designed with MedTech engineering challenges in mind—from early-stage prototyping to light manufacturing and test automation. Whether you’re building custom test fixtures or prepping for DV testing, they’re here to reduce bottlenecks and improve repeatability across your development workflows.

EZ Motion Automation Suite

No-Code, No-Wait Automation for Engineers

Automation is a common pain point in MedTech R&D. It’s often reliant on overstretched controls engineers or external integrators. For fast-moving teams, that delay can add weeks to a development timeline.

EZ Motion solves this problem by democratizing automation. It’s a plug-and-play system that lets engineers and technicians automate motion sequences and pneumatic actuation without writing a single line of code. Built for rapid deployment, it turns what used to be a 40-hour controls project into something you can implement in under 20 minutes.

Key Features:

- No-code software: Drag-and-drop interface designed for engineers and technicians, no programming background needed

- Plug-and-play setup: Pre-integrated motor and pneumatic controllers—no need to source external power supplies, terminals, or valves

- Compact control: Supports up to 4 motors and 4 pneumatic actuators, along with sensor inputs

- Fast configuration: From unboxing to running a motion sequence in under 20 minutes

Perfect For:

- Design Verification (DV) testing

- Proof-of-concept and lifecycle automation

- Replacing repetitive or manual assembly tasks

- Iterative fixture builds and validations

“This system gives control back to the R&D team,” says Pipeline’s engineering lead. “You don’t need to wait for someone to write code or wire up a cabinet. Just connect it and go.”

See the EZ Motion Automation Suite in action.

Threaded Insert Installer

Precision Insert Placement for Thermoplastics & 3D-Printed Parts

Whether you’re working with 3D-printed housings or injection-molded test components, installing heat-set inserts is a common step in MedTech prototyping. But doing it by hand—or with repurposed shop equipment—can lead to misaligned inserts, inconsistent depths, and rework that eats up valuable time.

Pipeline’s Threaded Insert Installer was built specifically to solve this. Compact, ergonomic, and easy to use, it allows engineers and technicians to make clean, consistent insert installations every time—without needing specialized training or extended cooldown periods.

Key Features:

- Wide compatibility: Supports M2–M8 and 2-56 to 5/16-18 inserts

- Adjustable mechanics: 6.8″ throat, 0–8″ height, and 0–2.5″ stroke range

- Quick tip swaps: Swap tips fast, even while hot—no need to wait for the tool to cool down

- User-friendly grip: Ergonomic handle designed for ambidextrous use

- Consistent results: Stroke stops and alignment features help ensure uniform insert depth and position

Perfect For:

- Installing threaded inserts into thermoplastics and 3D-printed housings

- Building enclosures, fixtures, or jigs with embedded fasteners

- Engineering teams needing consistent insert depth and placement

- Rapid iteration cycles where speed and repeatability matter

- Reducing rework or inconsistencies in early-stage builds

The Threaded Insert Installer is especially useful for teams working with thermoplastics like ABS, PLA, or PC, where controlled heat and pressure are critical to achieving a reliable bond between the insert and the base material.

Why Tools Matter: Chamfr’s Commitment to Faster Development Cycles

Prototyping and testing aren’t just about what goes into the device—it’s also about how you build, assemble, and validate it. That’s why we offer more than just parts. From catheter punch tools, split die thermal bonders to mandrel straighteners, our Equipment, Fixtures & Tools category helps you get your development project done, faster. The latest additions from Pipeline Design & Engineering are just one more way we’re making it easier to move from concept to design freeze.

Frequently Asked Questions (FAQs)

No, please see our EZ Motor product for the motorized version.

Yes, the two products work seamlessly together via an ethernet connection so you can control motors and pneumatics at the same time.

8 generic 24VDC inputs (can be used for pneumatic position sensors). 1 24VDC input for Remote Starting a sequence.